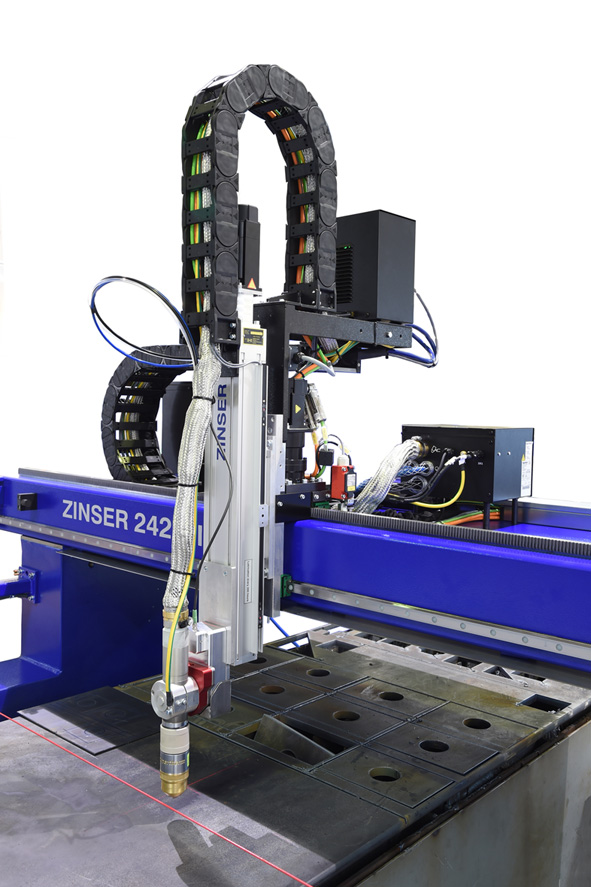

The flame cutting process consists of three operating cycles:

- preheating respectively fast preheating

- piercing

- cutting

For all of those cycles, oxygen and cutting gas with different pressures are required. With the proportional valves, the pressure for each individual cycle can be perfectly adjusted.

During the piercing process, the pressure of the cutting oxygen must increase continuously. With an additional potentiometer for the >cutting oxygen ramp<, the increase of pressure can be perfectly adjusted to the requirements to be cut. Furthermore, the lifetime of nozzles increases considerably.

Advantages

- central arrangement of the operating- and control device

- perfect adaption of gas pressures to the material requirements

- correction of gas pressure possible at any time

- contiuous, linear increase of cutting oxygen during piercing process

- increased lifetime of nozzles

- improved cutting quality