Compact cutting system / 1000 Series

Compact cutting system / 1000 Series For precise plasma and oxy-fuel cutting The guiding machine ZINSER 1225 is ideal for combined oxy-fuel and plasma cutting.

Home » Technology » Plasma cutting

Plasma cutting is used mainly for cutting high-alloyed steel and aluminum, as well as for thin plates of low-alloyed steel (mild steel).

Plasma cutting is a melting procedure, where the to-be-cut metal is melted by the plasma jet. A cutting gas jet is being heated up until it reaches the fourth state of matter, i.e. highly energetic plasma gas, and is being electrically charged (ionized) by the plasma power source. In order to focus the resulting plasma jet, which reaches up to 30.000 degrees Celsius, on the material, it is constricted by a fluidizing gas. Where the plasma jet touches the to-be-cut object, it transmits its energy and punctually melts the material. A secondary gas jet subsequently blows the melted material out of the kerf.

Energy consumption of plasma cutting is higher than oxy-fuel cutting, because the material needs to be melted along the entire kerf. Typical cutting gases include oxygen, nitrogen or argon/hydrogen mixes.

Low to medium

An excerpt from industries and possible areas of application for ZINSER plasma cutting systems:

Construction industry

Energy industry

Mechanical engineering

Steel industry

Ventilation construction

Metalworking

Vehicle construction

Shipbuilding

The company ZINSER is renowned around the world for its high quality and customized products “made in Germany”. ZINSER combines tradition with innovation and realises the needs of its customers. Our reputation as a world wide known company is based on our expertise in the field of plasma cutting systems.

compared to manual plasma cutters

Compact cutting system / 1000 Series For precise plasma and oxy-fuel cutting The guiding machine ZINSER 1225 is ideal for combined oxy-fuel and plasma cutting.

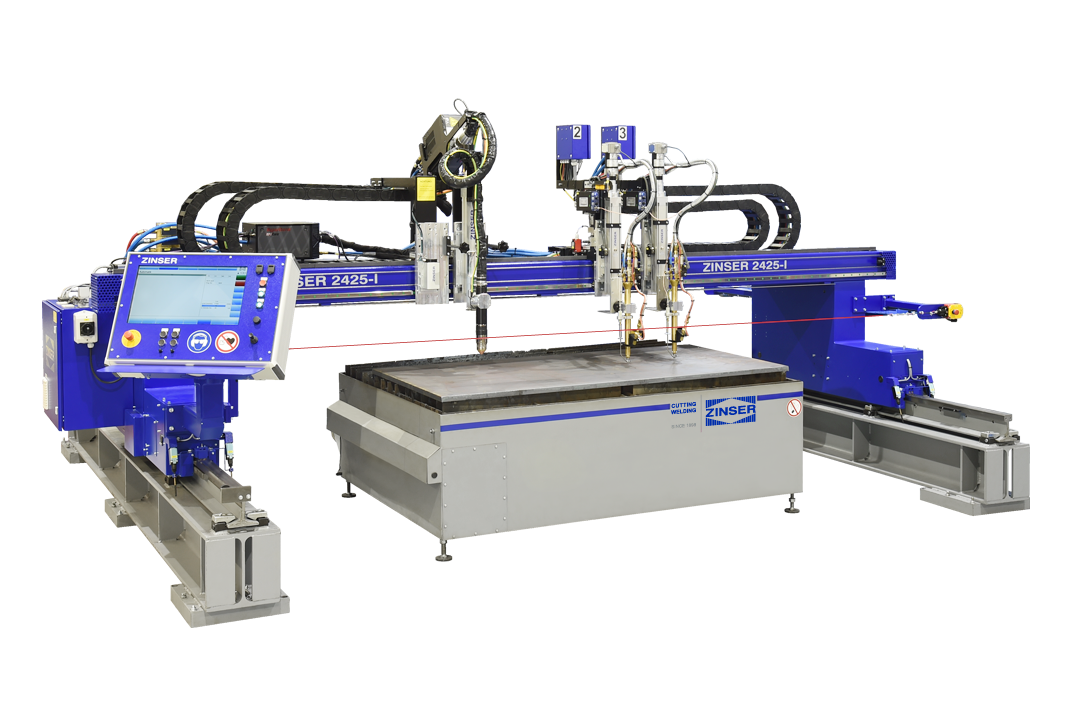

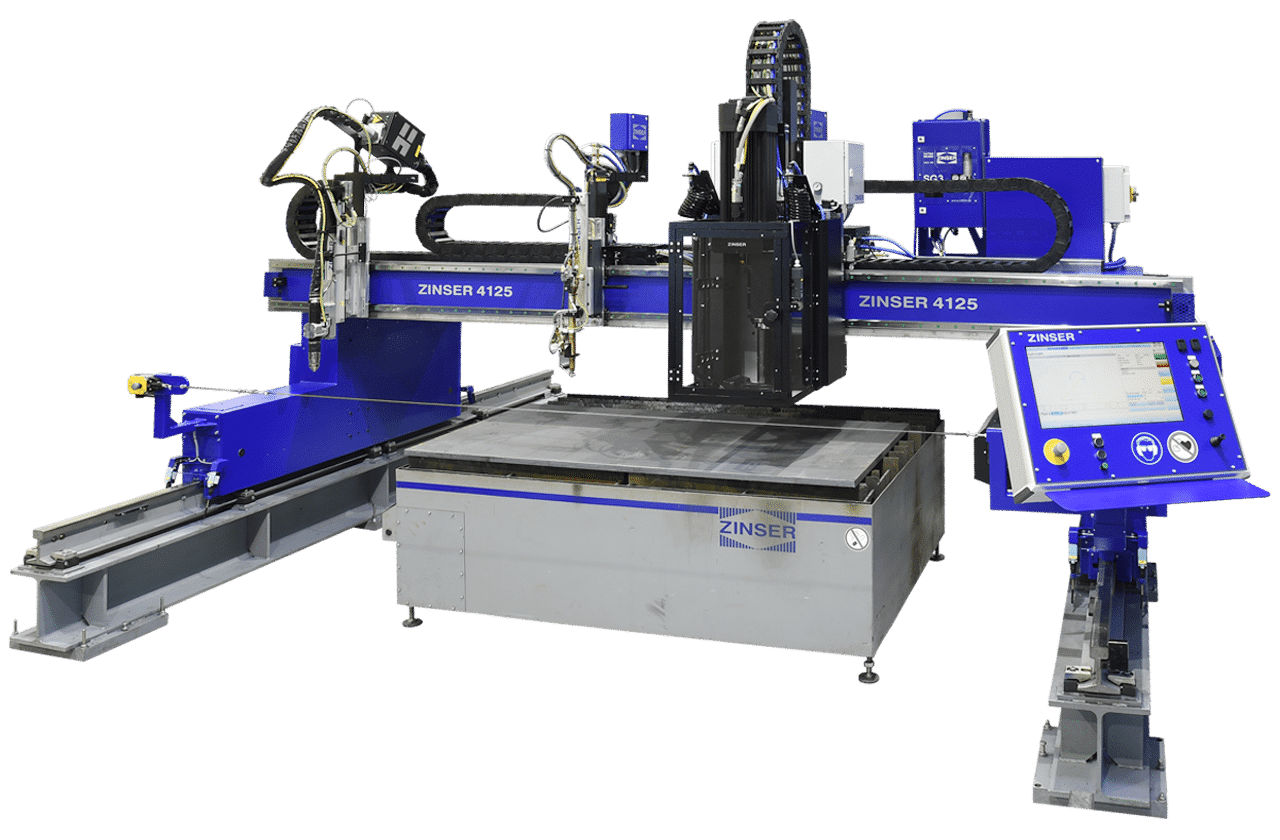

The highly dynamic ZINSER cutting systems with perfectly matched drives have been fulfilling customers‘ requirements from various industries all over the world for years.

CNC control for ZINSER flame cutting machines First-class CNC controller for the perfect operation of your flame cutting machines Some of your advantages with the

The machines of the ZINSER premium series are known worldwide for their excellent cutting quality.

Whenever an extraordinary machine reliability is required, like in the steel industry, customers have relied on ZINSER machines for decades.

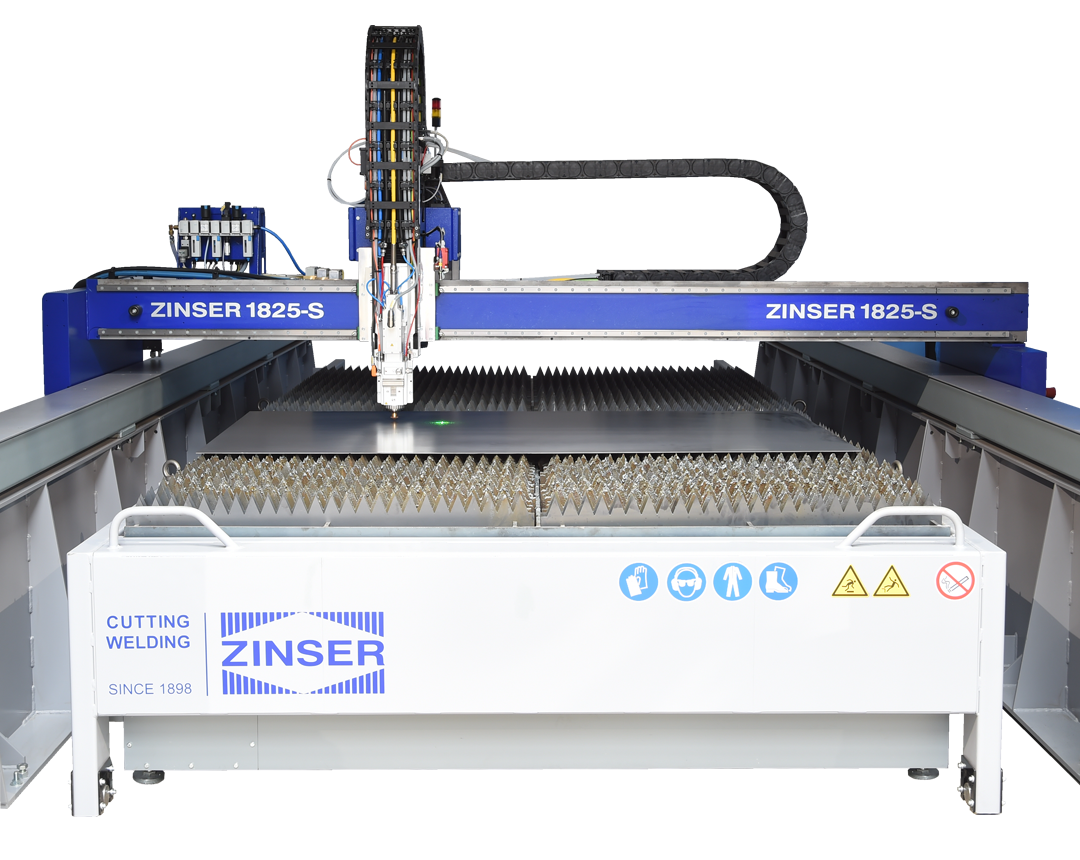

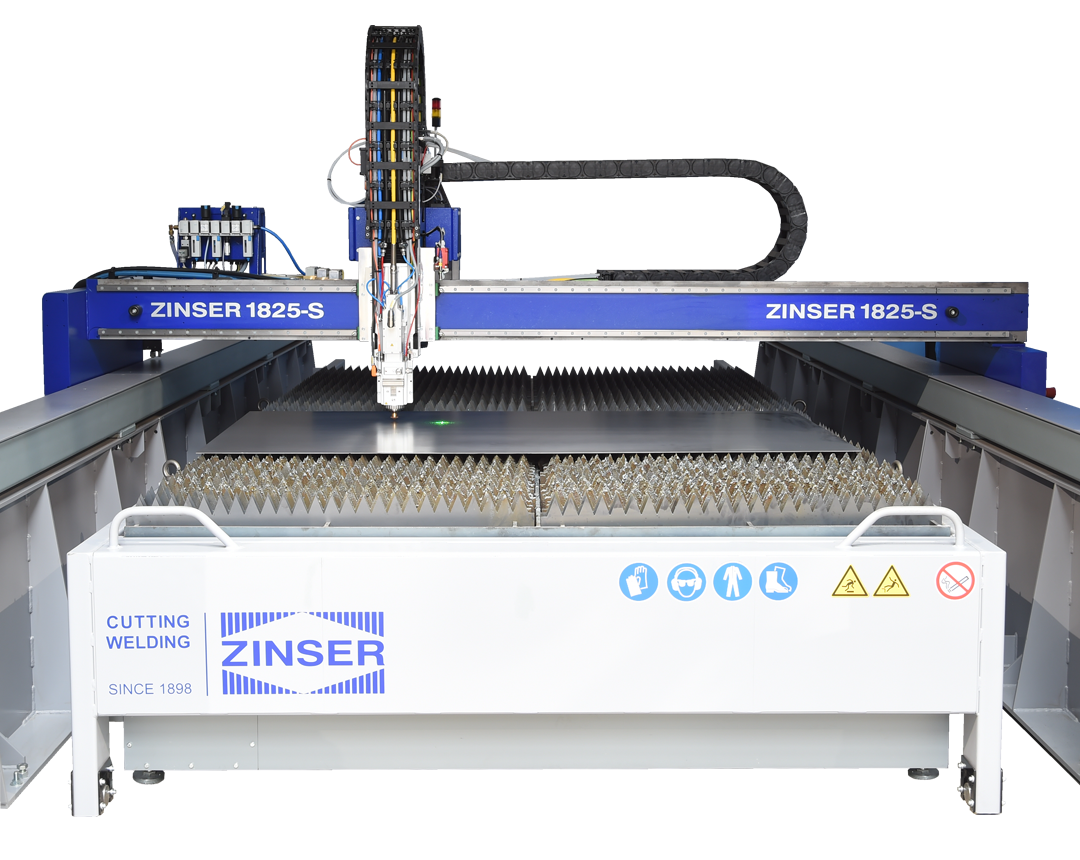

The ZINSER 1825-S Fiber Laser is a high-quality guiding machine for laser and plasma cutting and for combined cutting tasks. The portal machine unites the required speed and precision for laser and plasma cutting with the robustness and longevity of an industrial machine.

Tell us your task and we will find a solution together with you!

CNC plasma and oxy-fuel cutting machine

Quick and easy to use everywhere

We offer plasma cutting technology from the leading manufacturers Hypertherm and Kjellberg. As an OEM partner, you get all-in-one solutions from ZINSER for your plasma cutting machine.

Hypertherm is used wherever difficult cutting work is required.

With products from Kjellberg Finsterwalde, users receive plasma systems that are state of the art.

Our very large stock allows us to guarantee you the best delivery times: orders placed before noon are shipped the same day. We supply you with consumables of all brands at very competitive prices, and are OEM partners of leading plasma cutting manufacturers Hypertherm and Kjellberg. Ask us for an offer and compare our prices!

Orders placed before noon are usually dispatched the same day.

ZINSER GmbH is your strong partner in the areas of flame cutting systems, oxy-fuel technology and hot air devices. Quality and the satisfaction of our customers are our first priorities. Name your task and we will find a solution together!

Kontaktieren Sie uns telefonisch oder über das unten stehende Formular für alle Ihre Anfragen. Wir beraten Sie gerne!