Compact cutting system / 1000 Series

Compact cutting system / 1000 Series For precise plasma and oxy-fuel cutting The guiding machine ZINSER 1225 is ideal for combined oxy-fuel and plasma cutting.

Home » Technology » Oxy-fuel cutting

In case of mild steel of higher thicknesses, oxy-fuel cutting is the qualitatively optimal cutting procedure. Although plasma and laser cutting has gained in popularity, oxy-fuel cutting remains a highly economic cutting procedure, achieving good cut quality. In particular in case of material thicknesses of up to 1200 mm, oxy-fuel cutting remains the method of choice.

A flame of propane, acetylene or high fuel-value natural gas from a torch is used to pre-heat the to-be-cut material quickly to its ignition temperature (ca. 1050 to 1526 degrees Celsius. Subsequently, a gas jet of minimum 99,5% oxygen is blown onto the heated material, so the pre-heated material starts to burn. The torch is dragged further, and where the burnt material is missing, a narrow kerf occurs.

As this burning of material (oxidation) is an exothermic process, hence releasing energy and thereby feeding itself, the procedure is very energy-saving. The torch is only required to maintain the ignition temperature along the kerf.

Low

Read more about oxyfuel technology : Hypertherm website

Compact cutting system / 1000 Series For precise plasma and oxy-fuel cutting The guiding machine ZINSER 1225 is ideal for combined oxy-fuel and plasma cutting.

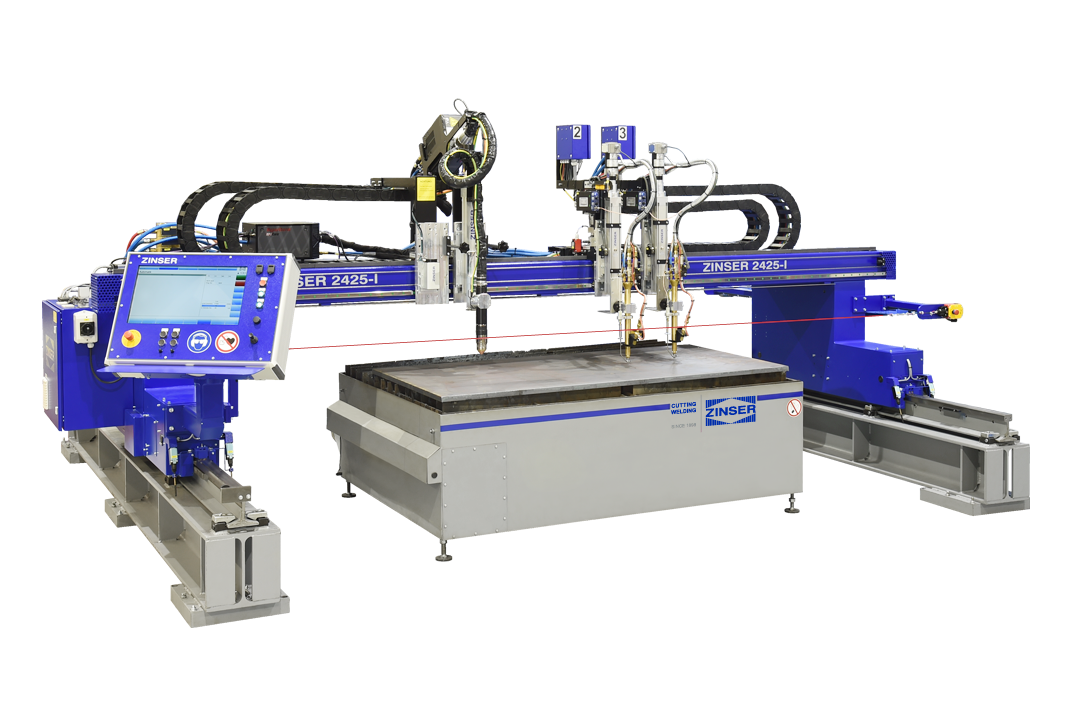

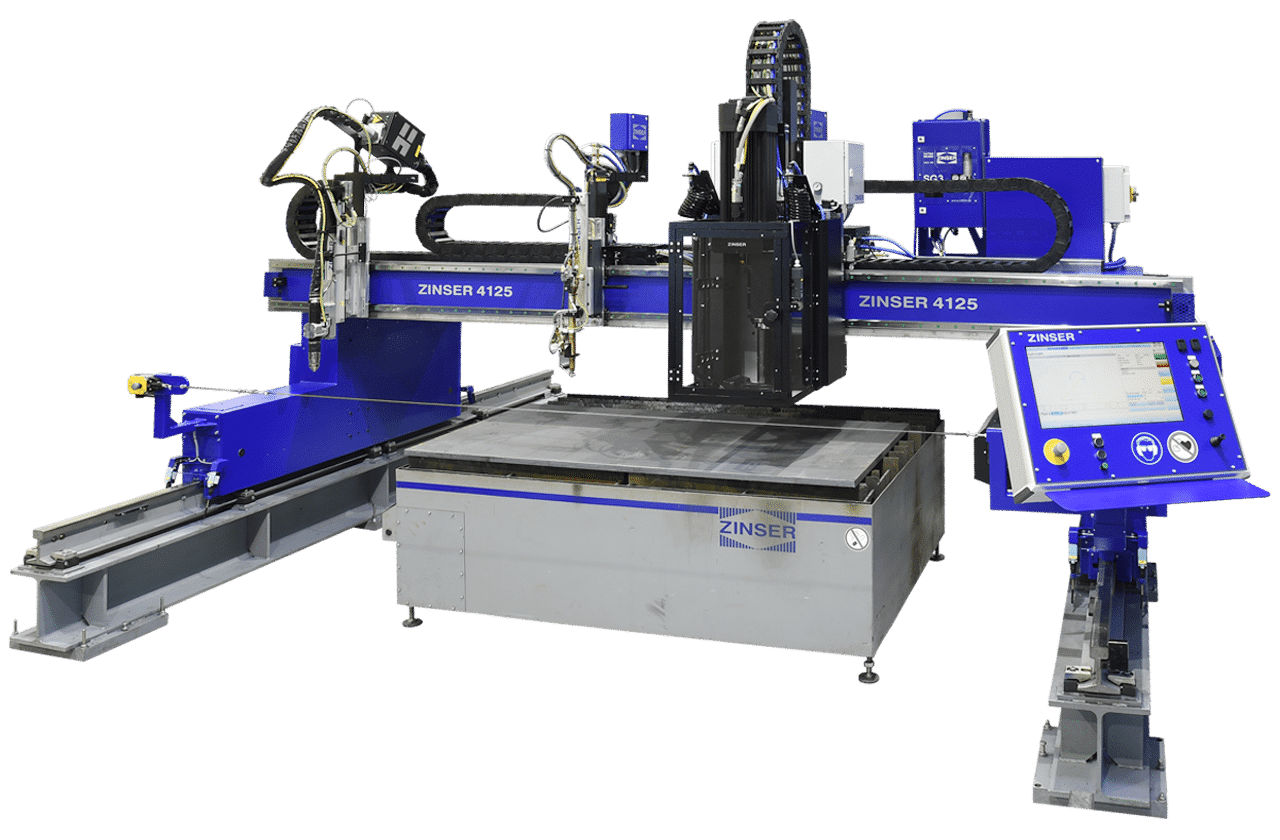

The highly dynamic ZINSER cutting systems with perfectly matched drives have been fulfilling customers‘ requirements from various industries all over the world for years.

The machines of the ZINSER premium series are known worldwide for their excellent cutting quality.

Whenever an extraordinary machine reliability is required, like in the steel industry, customers have relied on ZINSER machines for decades.

Tell us your task and we will find a solution together with you!

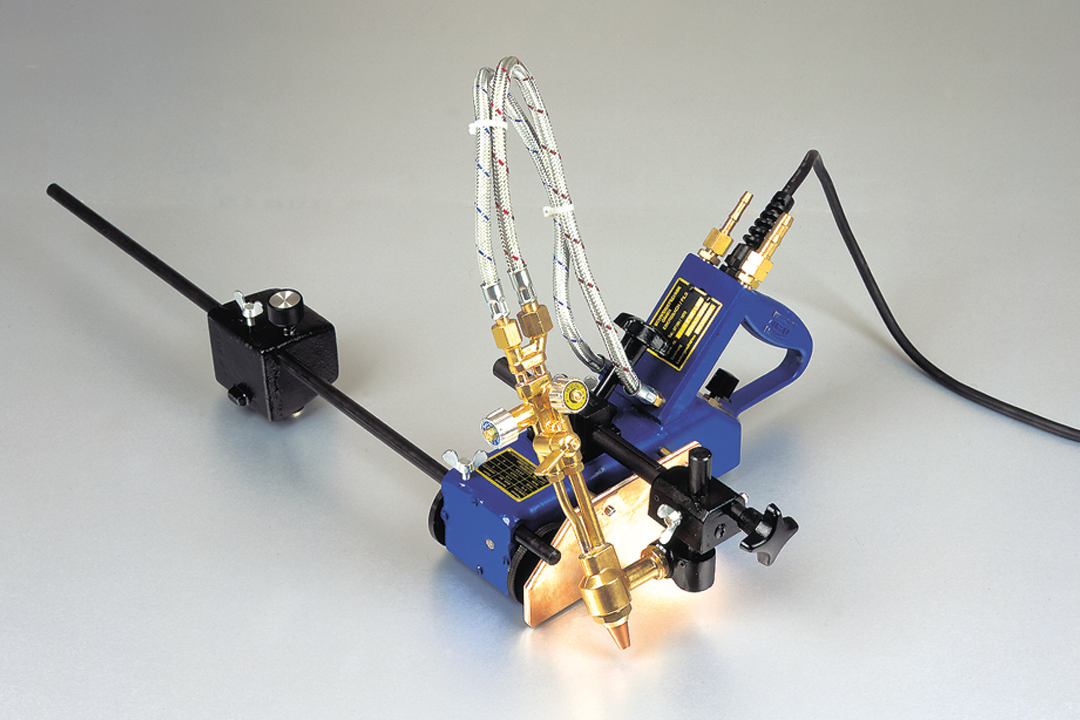

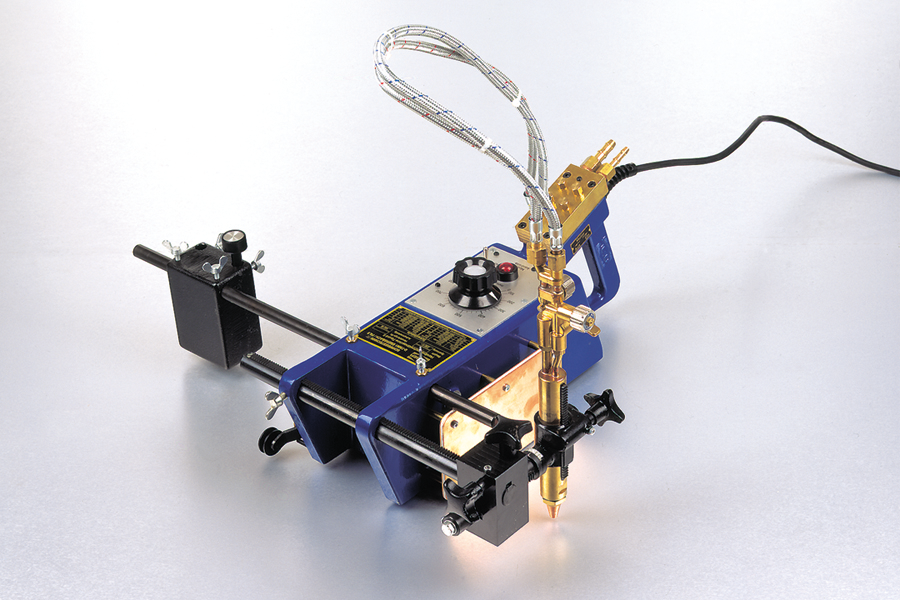

The ZINSER Favorit I & Favorit II are portable flame cutting machines with infinitely variable drives.

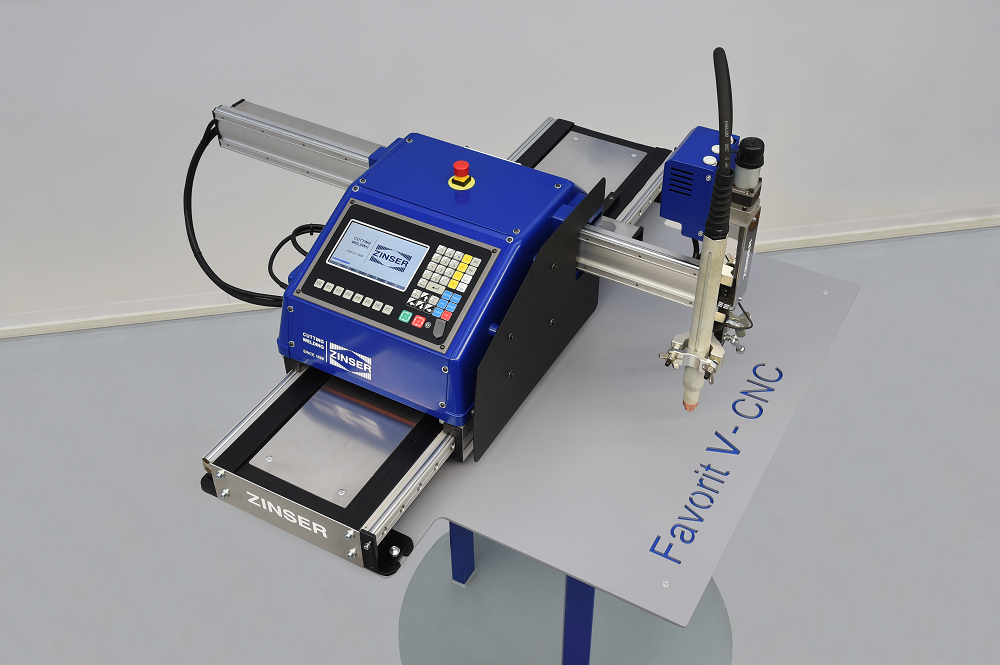

ZINSER Favorit V : portable CNC plasma and oxy-fuel cutting machine

for material thicknesses up to 60 mm (max. 100 mm)

for material thicknesses up to 250 mm

Portable cutting system

Quick and easy to use everywhere

For more than 100 years ZINSER has been exploring the use of acetylene and other gases.

Pressure regulators for cylinders, pressure regulators for distribution points, welding and cutting torches as well as complete sets from ZINSER are a worldwide synonym for quality.

ZINSER GmbH is your strong partner in the areas of flame cutting systems, oxy-fuel technology and hot air devices. Quality and the satisfaction of our customers are our first priorities. Name your task and we will find a solution together!

Kontaktieren Sie uns telefonisch oder über das unten stehende Formular für alle Ihre Anfragen. Wir beraten Sie gerne!