Since the beginning of this year, the preparations for the set up and installation of the new ZINSER 4125 plasma cutting machine at Hilgefort ran at full speed. The high performance system is the third ZINSER 4125B Hilgefort has invested in. Started in April, the ZINSER machine now significantly increases the flexibility of Hilgefort’s contract manufacturing department.

The ZINSER 4125B is equipped with an automatically rotating bevel cutting head, an oxy-fuel torch and the CNC drilling unit with 14000N infeed. The drilling unit allows the drilling of holes with diameters of 6 to 40 mm through plates with a thickness of up to 250 mm (first hole). As additional equipment, Hilgefort chose Hypertherm’s HPR400D as plasma power source and ZINSER’s oscillating conveyor table ZINtrac.

“Hilgefort is a long-standing customer“, remembers ZINSER’s Managing Director Ulrich Bock. “We’ve been working successfully together since 1989. Therefore, it makes us especially proud, that Hilgefort chose once again a ZINSER.”

At Hilgefort, cuts are made without any problems on the ZINSER, using a wide range of materials, from carbon steel, stainless steel and aluminum to copper. Especially the manufacturing of 3D contours in a radius is an additional highlight of the machine.

With the new ZINSER, Hilgefort has increased its production capacities and can thus fulfill customers’ requests even faster. The three ZINSER systems enable Hilgefort to be highly flexible and complete a larger amount of contract manufacturing orders. “Thanks to the increased capacities we can now manufacture orders faster, at a lower price and with very short lead time”, explains Florian Rönker of Hilgefort’s the contract manufacturing department.

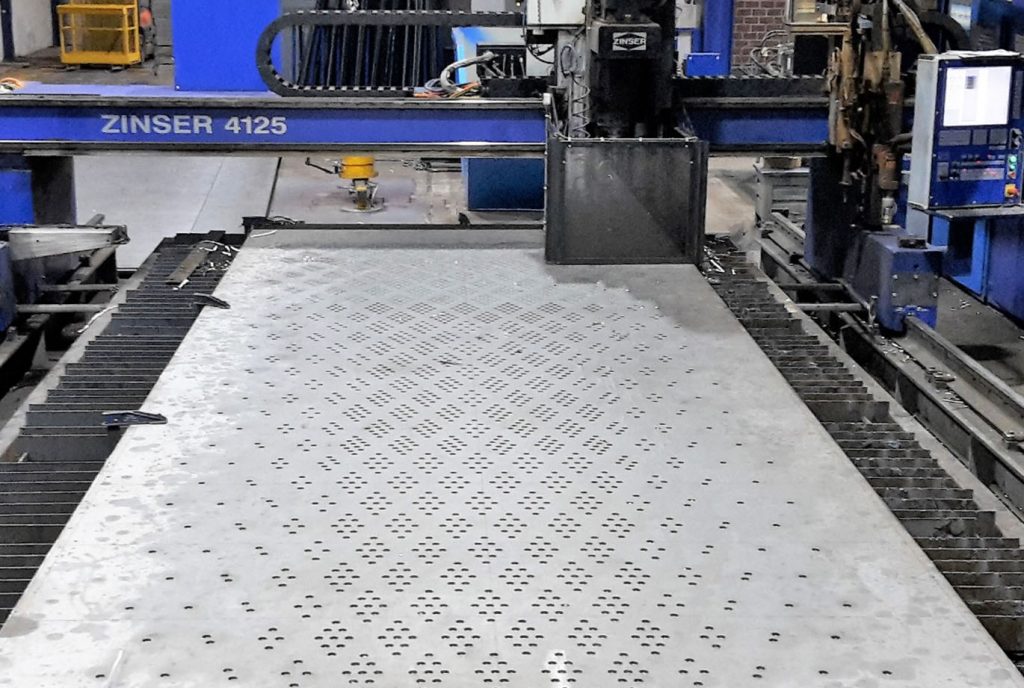

First drilling task for the new ZINSER system

The new ZINSER 4125B recently completed its first big project with the integrated CNC drilling unit.

Big plates (8.2 x 2.4 m) of an unusual, difficult to machine 1.4462 Duplex material had to be drilled within a short period of time. Requested were holes with a top diameter of 20 mm and a bottom diameter of 15 mm. No problem for the new drilling unit and a further advantage for Hilgefort’s customers, as there are just very few manufacturers who can offer this service due to the extraordinary bore diameter in combination with the large plate size. “Before investing, we gathered extensive information about the various drilling alternatives for cutting machines available on the market”, explains General Manager Ulrich Hilgefort. “But our engineers discovered very fast, that ZINSER’s drilling unit is far superior to its competitors‘. That’s why, again, we invested in a ZINSER system – the right choice, as this first successful task showed.” With a special tool, produced only for this task, every hole was drilled twice, resulting in a total sum of 28400 drillings. Despite this complex manufacturing process, the task could be fulfilled within approx. 500 working ZINSER hours.

Through this first task alone, the new ZINSER system could already prove itself. Today, the 4125B is fully functional and integrated into the production processes at Hilgefort. CEO Ulrich Hilgefort is already looking forward to many new, varied tasks for their contract manufacturing department. “The new ZINSER system increases our capacities significantly, allowing us to offer our customers additional production possibilities”, says Ulrich Hilgefort.

If you are interested to see a ZINSER drilling unit near your location in action, please don’t hesitate to contact us at any time. We are looking forward to organizing a visit for you.