Founded in 1898, the family business ZINSER GmbH is a specialist in manufacturing cutting systems, software as well as oxy-fuel and hot air devices. With the Salzgitter Mannesmann Handel GmbH, the leading company in the area of trading in the Salzgitter Group, ZINSER has been holding a strong partnership for years. Today the Salzgitter Group operates several ZINSER portal machines at different locations in various countries for added processing of plates.

The common commitment to high quality standards unites

When it comes to steel, Salzgitter AG is one of the leading experts. Founded in 1858, the Salzgitter Group stands for innovative and sustainable production of steel and technology products. Today the international group employs about 25000 people who work daily to offer innovative and sustained products of the highest quality to customers from different industries.

To produce innovative high-quality products made in Germany has always also been one of the main goals the machine manufacturer ZINSER has been committed to. This common ground in both company philosophies led to the first contact, and in 2012 the first cutting system was sold to the Salzgitter Group.

Close partnership leads to success

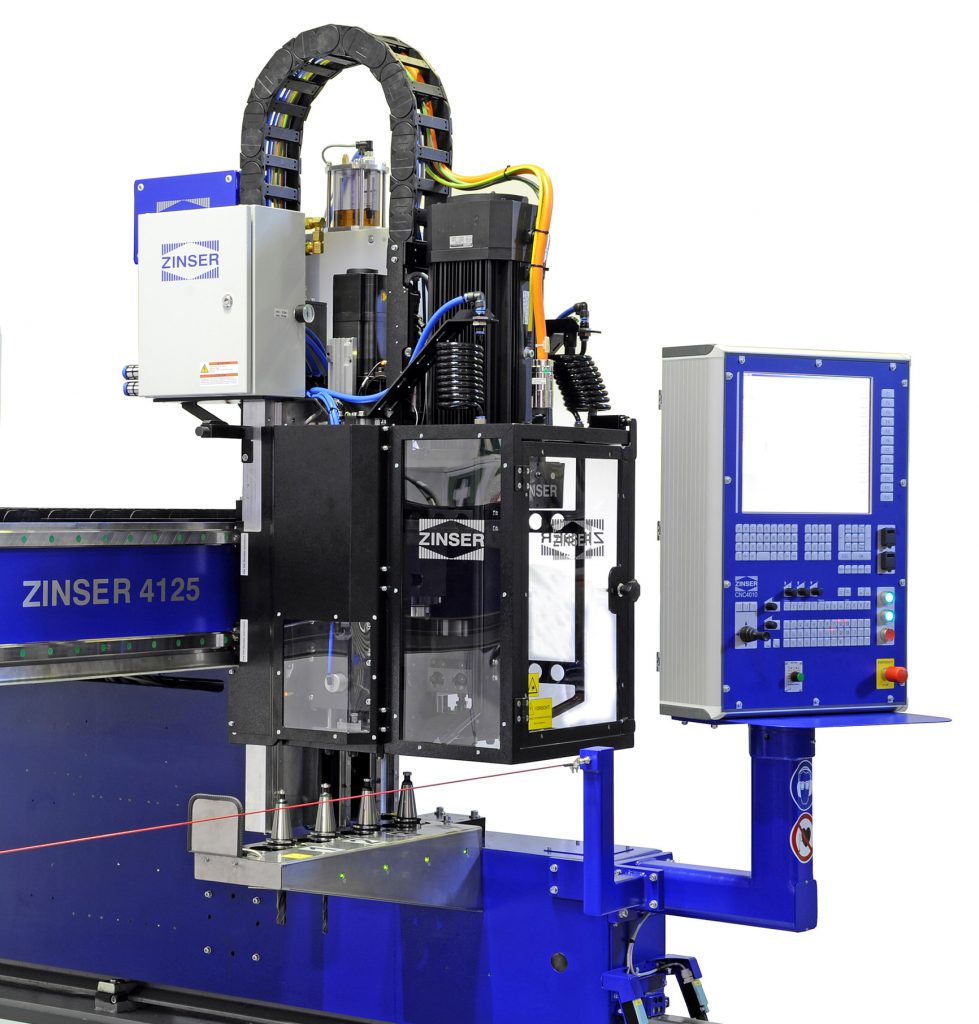

Due to the complete satisfaction with its first machine, further orders from different Salzgitter locations followed. In 2015, a ZINSER 4125 was installed at the Salzgitter Manensmann Stahlhandel GmbH in Hanover.

Salzgitter Mannesman Stahlhandel GmbH is the sales partner of the steel works of the Salzgitter Group and responsible for stockholding steel trading in Germany. True to the motto “Systems. Service. Steel.” customers worldwide are supported with a wide range of added processing. Modern technology allows almost every form of added processing of plates, profile steel and pipes for the final assembly to be conducted accurately and with a premium quality.

“The crucial factor for the choice of a ZINSER cutting system was the excellent reputation of the ZINSER machine at our location in Plochingen and the personal support of ZINSER’s managing director Ulrich Bock. He convinced us with great commitment and dedication and addressed all our questions and concerns”, explains Michael Launer, site manager in Hanover.

Increased added value and acquisition of new customers

The excellent relationship with ZINSER was not the only reason for the purchase. “Thanks to the portal machine ZINSER 4125, a plasma cutting system with integrated CNC drilling unit and bevel head, we could increase our added value and win new customers”, adds Michael Launer. The short delivery time was another advantage. “After the Group decided to purchase a new plasma cutting machine in the middle of 2015, the ZINSER cutting system was already installed in November”, explains the Salzgitter manager very pleased.

Advantage through leading technology

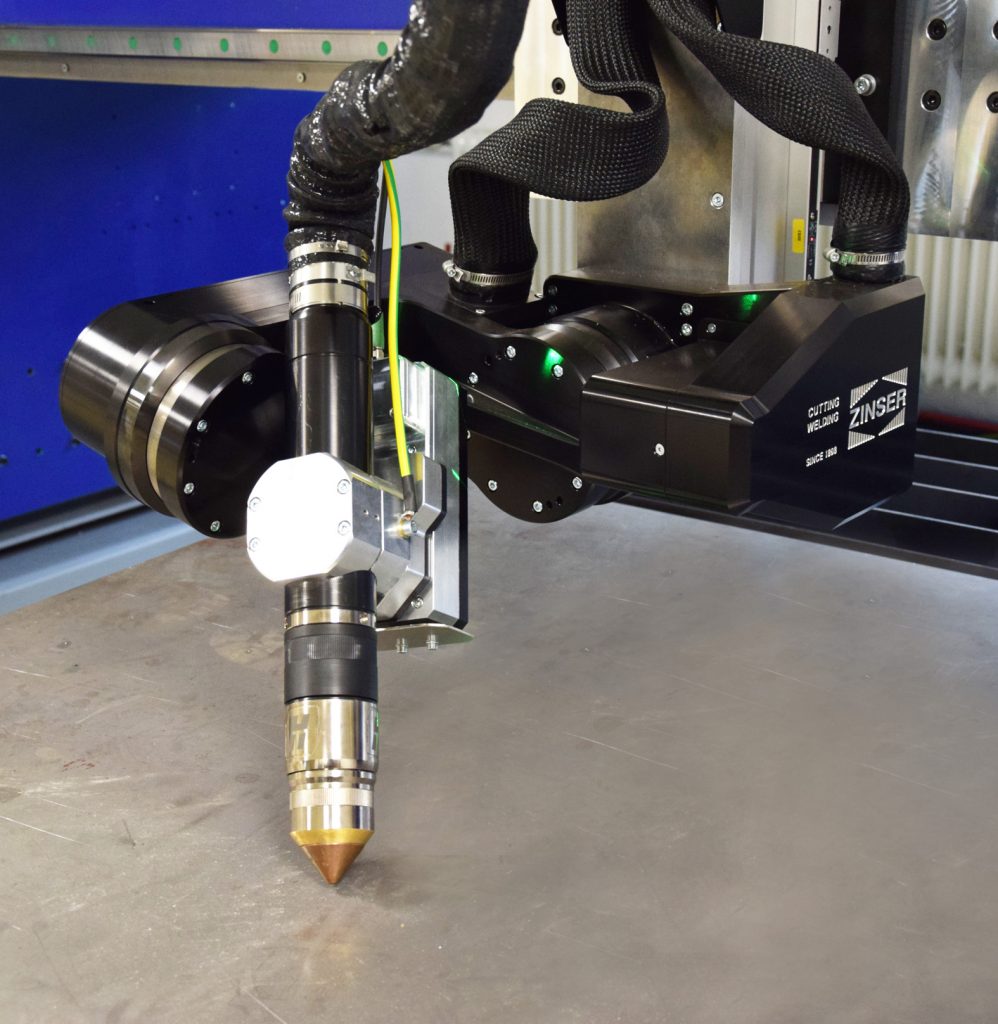

The ZINSER portal machine 4125 is equipped with the newest plasma bevel headFasenschneiden 2015 which covers V-, A- and top-V style cuts from 0° to +/- 45°. To ensure high-quality plasma cuts, Salzgitter chose the plasma power source HPR 400XD from world market leader Hypertherm.

The additional CNC controlled drilling unit MAX 40R with automatic tool changerCNC-Bohren from ZINSER increased the flexibility in the processing of steel plates even further. The drilling unit with minimal quantity lubrication and a press capacity of 15000 newton allows the drilling of holes up to a diameter of 40 mm through steel plates with a thickness of up to 150 mm including countersinking and thread cutting. In order to fulfill the various requirements of Salzgitter’s customers, the machine has a track width of 5600 mm and a length of 28 m.

In general, Salzgitter Hanover cuts all plates with a thickness of up to 40 mm on the ZINSER machine, no matter which form the customer requires. Salzgitter customers from the steel or automotive industry as well as machinery or plant manufacturers can thus rely on the wide range of added processing of plates. “Each day approximately 100 different forms are nested and afterwards cut on the ZINSER machine, while the machine is operated in up to three shifts a day”, explains Michael Launer the demands of his customers.

The extraordinarily robust design, linked with a high stiffness, precise linear guides (ball rail systems) on the gantry bridge and a heavy duty runway, based on milled railway profiles S 49, guarantee the very best quality and a long duration of life. In addition the portal machine offers a wide range of tools and additional components like the mounting of up to 12 torch carriers on the gantry bridge.

The successful partnership continues

Salzgitter has recently ordered a second plasma bevel head for its ZINSER 4125, allowing the cutting system to become more efficient. Also, customers’ orders can be delivered even faster.

Due to the high satisfaction the Salzgitter site in Graz ordered another ZINSER 4125 in 2016 with a track width of 7700 mm. This machine is equipped with two oxy-fuel and two plasma torches, one of which is a bevel head. In 2018, Salzgitter Plochingen ordered their second ZINSER 4125 with one oxy-fuel and one plasma torch, a plasma bevel unit and a CNC drilling unit. For several weeks now the machine has proven to be the right choice.

By means of groundbreaking innovations and an exceptional customer support, Salzgitter and ZINSER have both established a strong market position which allows the two companies to be very optimistic about the future and the ongoing partnership of the two more than 100 years old traditional businesses.