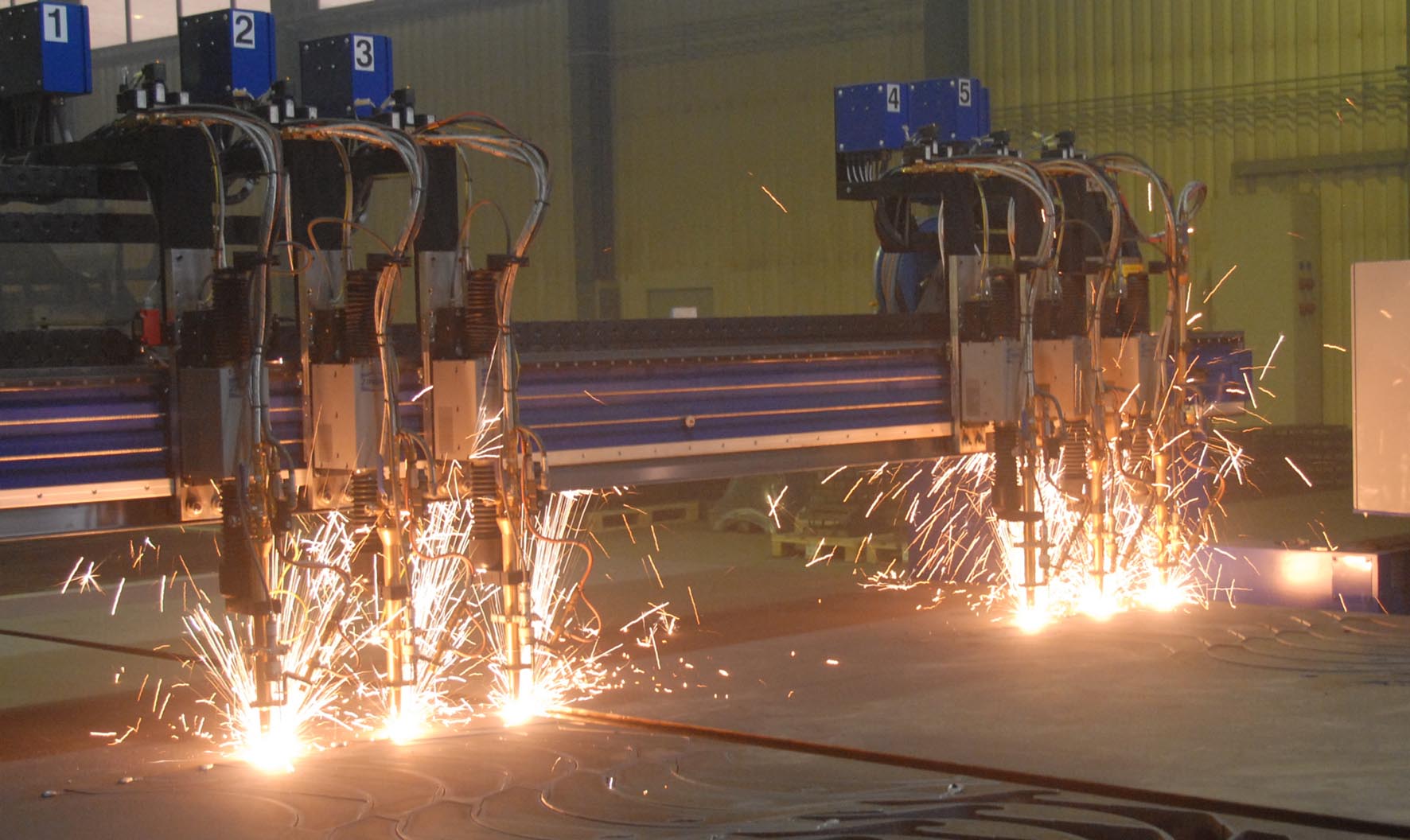

Cutting expert Winkelbauer counts on two new ZINSER 4025 cutting systems for the expansion of its production capacities. The highly flexible machines have been in use for almost a year now. Equipped with a plasma bevel head, oxy-fuel and plasma torches, the machines ensure a higher performance and quality in the Austrian family business‘s production. The additional equipment, like the in-ground, self-cleaning cutting table with oscillating conveyor, also excels.

Performance and professionalism are essential

Since 1945, the Winkelbauer GmbH has developed from a former blacksmith’s shop into one of the leading Central European companies, when it comes to construction machinery and the processing of highly wear-resistant steel. At the company’s 10,000 m² production site in Anger, Styria, 120 employees process up to 5,000 tons of steel a year.

In 2017, Austria’s biggest HARDOX®-processor decided to further enlarge its production capacities. This investment became inevitable due to the increased demand for its extensive product portfolio of wear parts as well as its wide range of excavator and wheel loader equipment.

After an extensive evaluation process, Winkelbauer decided to purchase two new ZINSER 4025. “As this was a crucial investment for us, we studied all solutions available on the market closely”, explains Winkelbauer’s CEO Michael Winkelbauer. “In the end, ZINSER convinced us once again with the exceptional performance of its cutting systems and the total package offered.“

A strong duo meets all requirements

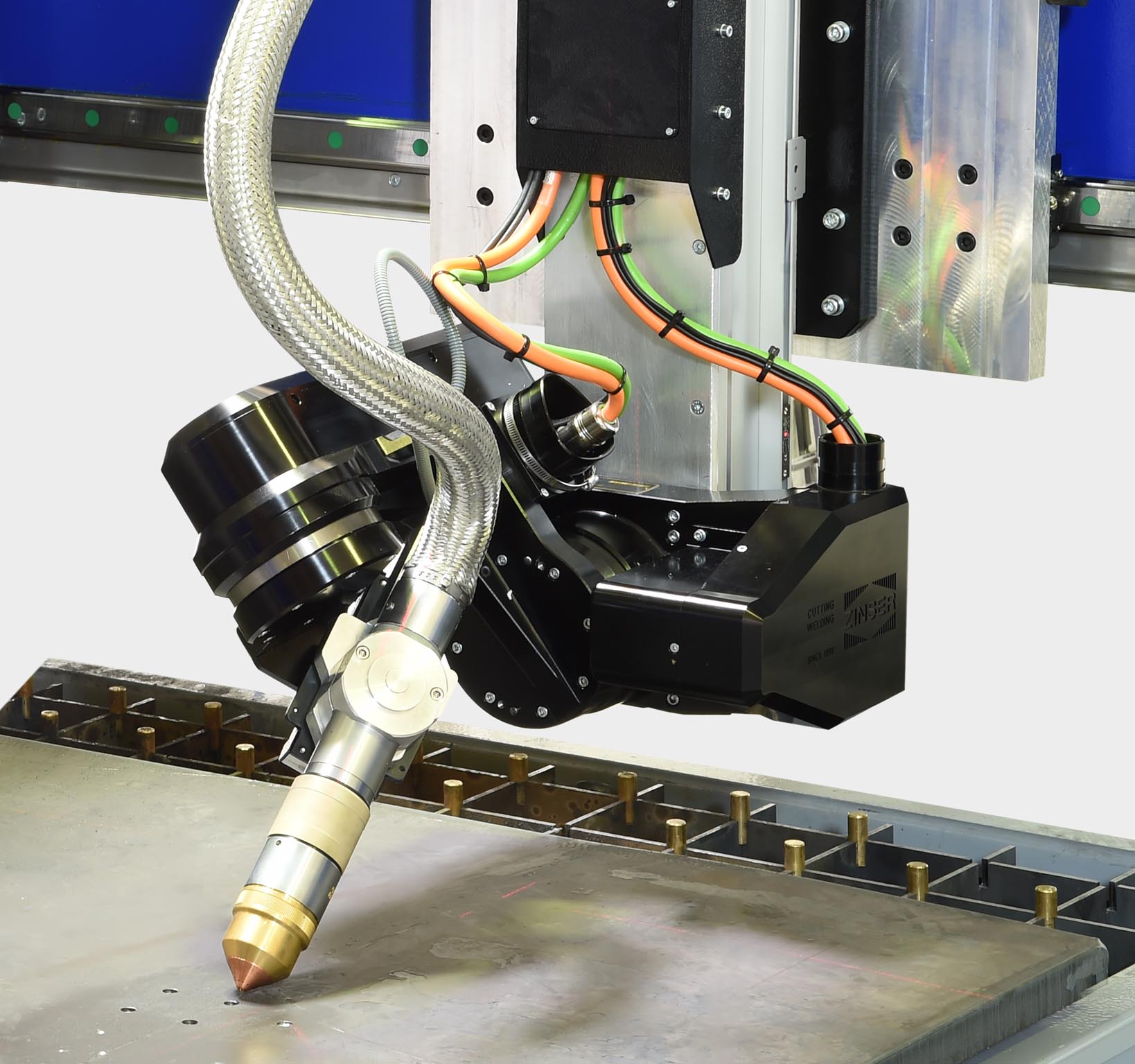

Winkelbauer manufactures a wide range of different parts, including straight and bevel cuts. More than 100 cutting jobs with at least 100 different shapes and parts are processed every day. For plasma cuts, the plate thicknesses range from 1 to 50 mm. For oxy-fuel cuts, thicknesses go up to 150 mm. The material to be cut ranges from S355 to HARDOX® and other highly wear-resistant steel. This wide task range in combination with plate sizes of up to 12,000 mm lengths demands a highly flexible cutting system. Therefore, Winkelbauer chose a combination of two ZINSER 4025 with different cutting equipment.

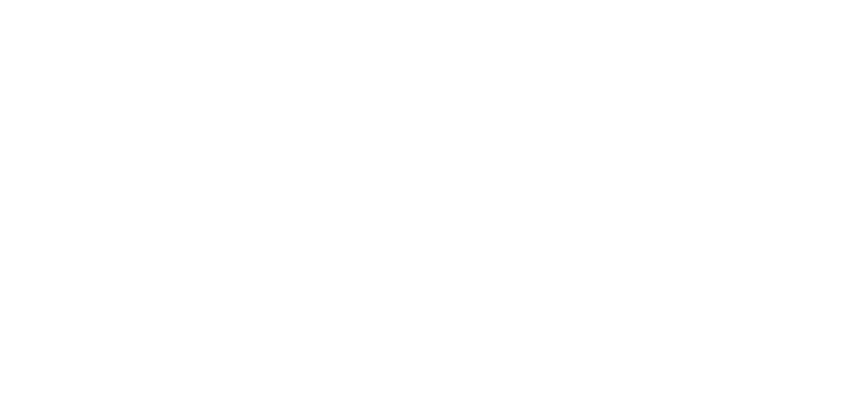

The first machine is equipped with two oxy-fuel torches and a HyPerformance plasma torch. The plasma torch includes an arc voltage height control ZAC 5070. The height control has been designed to ensure a fast data transfer to the plasma source and an exact positioning of the plasma torch during piercing and cutting within 0.025 mm. The ZAC 5070 works with a max. positioning speed of 15,000 mm / min and allows a high reproducibility by means of micro process control and monitoring. At the same time, all moving mechanical parts are protected twice against slag or plasma dust.

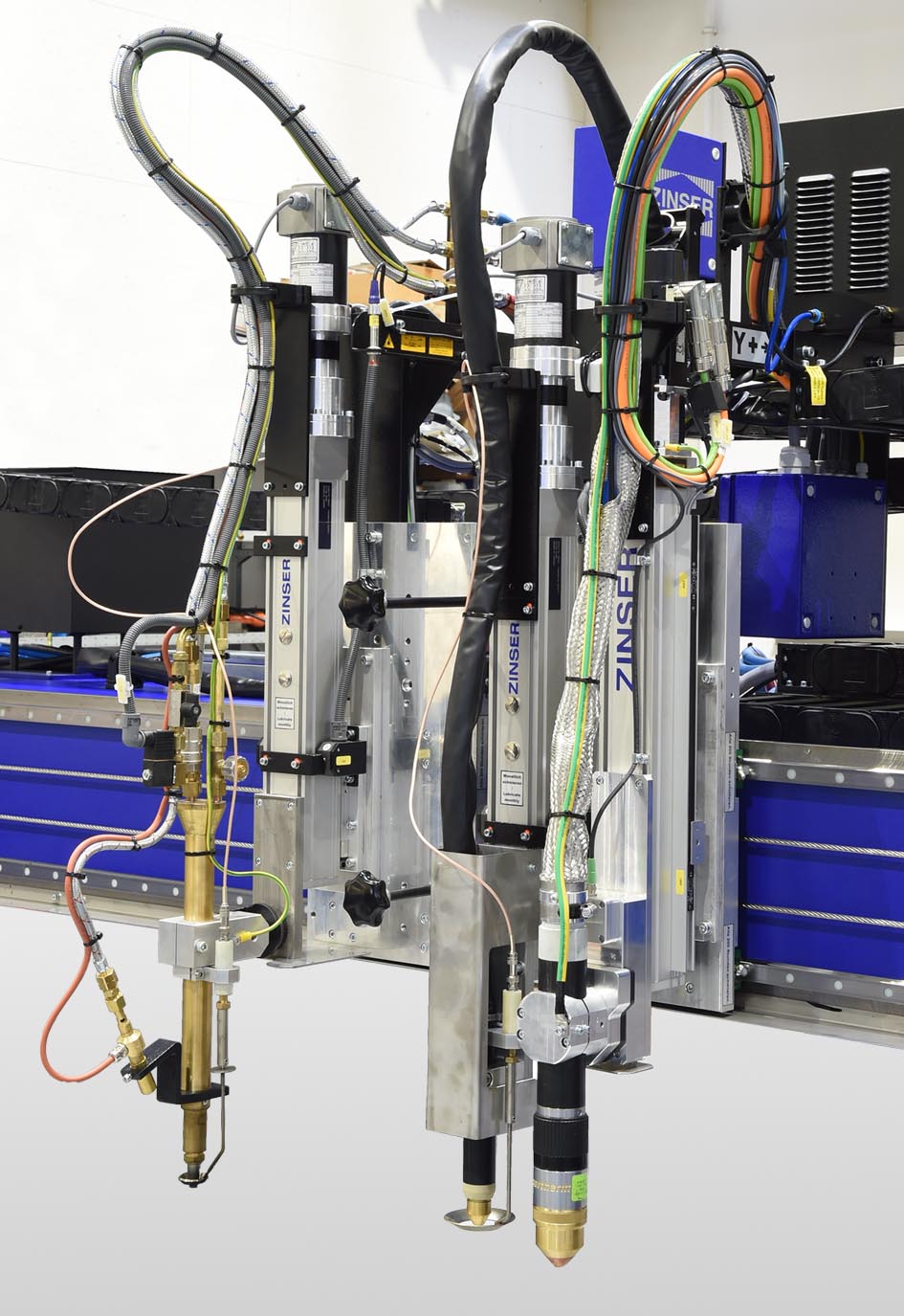

Winkelbauer’s second cutting system is equipped with ZINSER’s plasma bevel head. It is fully programmable, thus enabling the cutting of parts with bevels as well as vertical cutting edges. The plasma bevel head covers A-, V- and top-Y-style cuts from 0° to +/- 45°. The unit is driven by high-quality AC servomotors in three directions: inclination, rotation and height.

The True Bevel[TM] technology integrated into the ZINSER plasma bevel head allows the cutting of exact and constant bevels and substantially reduces the set-up time of new jobs, leading to higher productivity, more output and less material waste. The related True Hole® technology, installed on both machines, furthermore guarantees significantly better hole quality.

Both machines are additionally equipped with a plasma marking system for the marking, notching and graining of carbon steel, stainless steel and plates treated with primer, even with wet or oily surfaces. The infinitely variable marking power can be tailored exactly to the required task.

In order to ensure a high plasma cutting quality, Winkelbauer chose market leader Hypertherm’s plasma power source HPR 400XD. The versatile 400-amp rated system combines fast cutting speeds, rapid process cycling and quick changeovers with a high reliability.

“The two new ZINSER cutting systems increased our performance and quality immensely. We are cutting standard parts almost completely unmanned and see great potential for bevel cuts”, describes CEO Michael Winkelbauer the improvements resulting from the new machines.

Full package from one provider

The two ZINSER cutting systems with their track width of 4,100 mm were positioned on a shared running track with a total length of 25 meters. Thereby, Winkelbauer gained a great amount of flexibility and can now cut everything from numerous small to extremely large plates. The tracks were mounted directly onto the ground, so there are no barriers through HEB beams.

The powerful ZINSER duo works above a joint cutting table with oscillating conveyor. To guarantee a perfect working height, the cutting table has been positioned into the ground. The self-cleaning cutting table offers an intelligent transportation solution for all kinds of thermal cutting processes in combination with a highly effective exhaustion system. Scrap from the cutting process and small parts fall onto vibration chutes at the bottom of the table and are carried out through permanent vibrations. The small parts are free of slag because they continuously move in the direction of conveyance. Production downtime needed for the time-consuming emptying of the slag container becomes redundant. The automated cutting process becomes even more efficient.

“The overall concept from ZINSER with the installed machines, the in-ground cutting table and the exhaustion system is perfect”, confirms Michael Winkelbauer.

Looking at the topic of heat recovery, Winkelbauer went even one step further. The dust exhaustion has been combined with a heat exchanger, so the cutting energy can be used to heat the halls in the winter and cool them in the summer. In the corresponding area of 1,000 m² Winkelbauer is CO2-neutral. Even at -20°C outside temperature, the hall is perfectly heated with 100% pre-heated fresh air.

Long-standing partnership deepened

The investment in two new ZINSER cutting systems marked a further, important step in the long-standing and close partnership between both companies. In December 1965, Winkelbauer had bought its first cutting machine with an oxy-fuel torch from ZINSER. In the following years, four further systems followed, of which the ZINSER 4125BN from 2008 with six oxy-fuel torches is still in use today. The new ZINSER duo, replacing an old ZINSER machine from 2004, has so far been the largest joint project between the two family businesses. At the same time, the project handling and implementation has been the most complex, as the time frame for the set-up had been very short and the old machine had been in use until the new ones were fully functional. Only due to the close and highly professional cooperation between both companies, could the project be smoothly implemented.

“We are very happy, that we have once again been able to convince Winkelbauer of our machines. It is always a big success for us, if we can support our customers by means of our machines and our commitment to strengthen and expand their market share”, explains Andreas Niklaus, CEO at ZINSER.

The name Winkelbauer stands for perfectly cut parts. No matter the thickness, all Winkelbauer parts have an exceptionally smooth and grooveless surface. This goes along with a first-class outer appearance and product quality regarding the prevention of cracks. Thanks to ZINSER‘s plasma systems, Winkelbauer can achieve this excellent quality, that can almost compete with laser cut parts.

![[:de] Mit den ZINSER Autogenschneidmaschinen können auch sehr dicke Bleche problemlos bearbeitet werden. [:en] With the ZINSER oxy-fuel cutting machines, even very thick plates can be cut.](https://zinser.de/wp-content/uploads/Fachartikel_Winkelbauer_Schneidbeispiel_1.jpg)

![[:de] Brennteil mit runder Fase, Plasmaschnitt [:en] Flame cut part with round bevel, plasma cut](https://zinser.de/wp-content/uploads/Fachartikel_Winkelbauer_Schneidbeispiel_2.jpg)