Oxy-fuel:

- Digital piercing unit with database for plate thickness up to 200 mm

- Electrical ignition unit

- Automatic torch height control

- Automatic torch positioning (for multi-torch use)

- Single or triple torch beveling devices

- Single torch addressing

Plasma:

- CNC controlled data communication to plasma power source with automatic gas console, cutting data is sent directly from the CNC controller to the system (database) with automatic setting

- Arc voltage height control with data connection and automatic communication

- Full or semi-automatic beveling devices

Marking units

- Plasma marking

- Inkjet

- Needle marking

- Drilling unit

- Punching unit

- Powder marking

CNC-Drilling unit

- For holes up to 40 mm diameter (in plate of 100 mm)

- Automatic tool changer for drilling unit

- With broken drill detection device

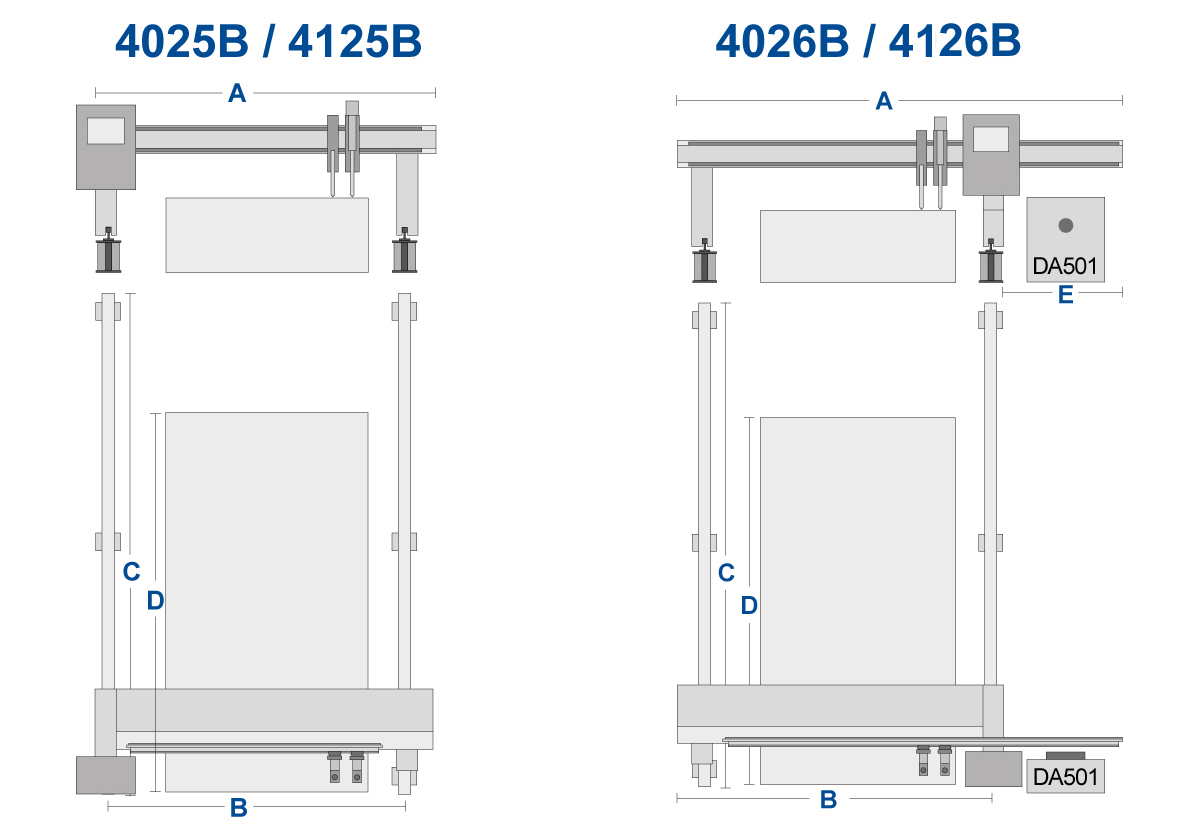

Machining of pipes and beams (only 4026B / 4126B):

- Cantilever up to 2000 mm

- Rotating axis for pipes up to 1000 mm diameter