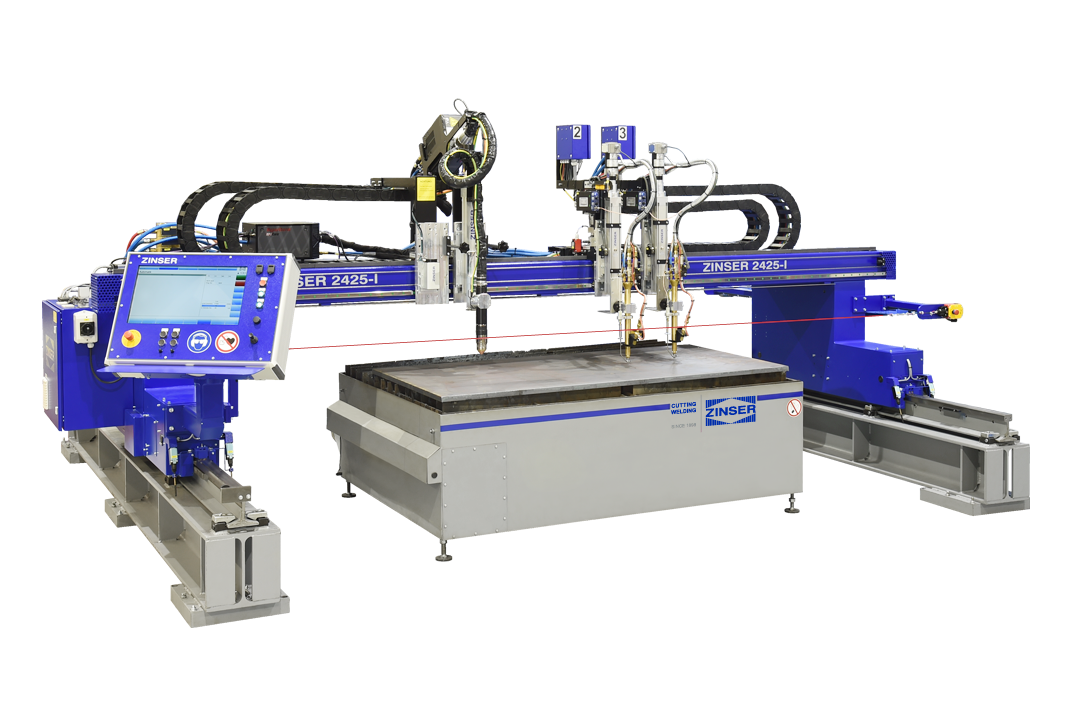

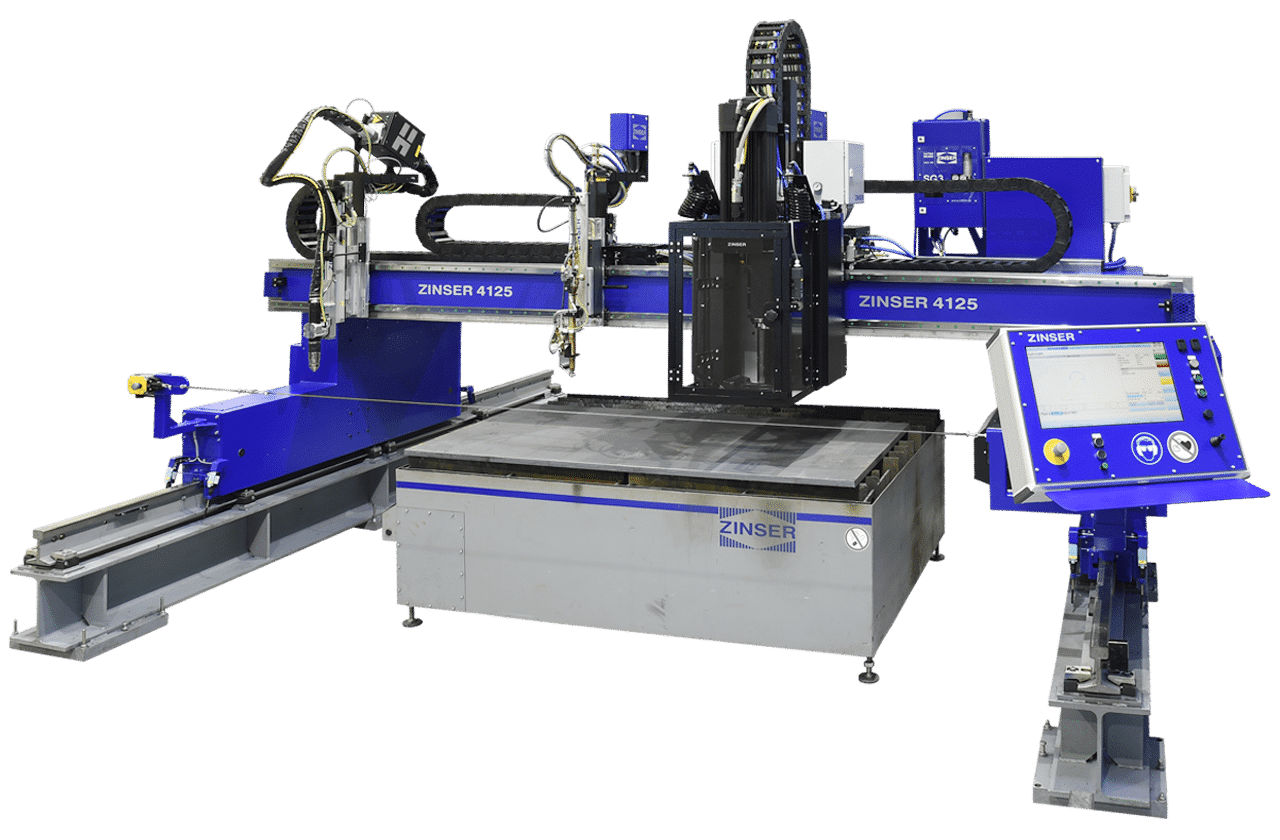

Premium cutting machines

The machines of the ZINSER premium series are known worldwide for their excellent cutting quality.

Whenever an extraordinary machine reliability is required, like in the steel industry, customers have relied on ZINSER machines for decades.